Revolutions in technology are rare.

More often, we see systems and processes evolve slowly over time. Improvements tend to be more incremental than fundamental.

That’s not the case with V-Warp® technology.

While elements of this radical new approach to boat building have been refined over recent years, the combination of them is both new and revolutionary.

Watch our short film about V-Warp’s Power of Three.

The extraordinary benefits of V-Warp® Technology are derived from what we like to call, ‘the Power of Three’ – the synergy of three design theories that have been fused into one manufacturing process.

These are:

Hull form – the development of an underwater geometry that leads to enhanced hydrodynamics and performance.

Exotic Materials – the use of superior e-glass, grade-A epoxy resins and carbon fibre to reduce weight while increasing strength.

Build Philosophy – the combination of reciprocal engineering and weight redistribution to optimise rigidity and balance.

Sit behind the helm of any model built with V-Warp® Technology and you’ll experience a series of phenomena firsthand.

You’ll be surprised at how easily the boat reaches plane speed and how quiet and soft the ride remains. You’ll be impressed and reassured by the poise and responsive handling you experience in all conditions. And you’ll be astonished to see that the boat is using about half the fuel of any motor yacht of a comparable size.

But to fully understand the ‘Power of Three’, it’s probably best to explore them one at a time.

The inspiration for the V-Warp® hull form is to be found in the world of competitive ocean racing.

Mark Richards, our CEO, spent ten exciting years on the match racing Grand Prix circuit and holds the unique honour of having won the Rolex Sydney to Hobart yacht race nine times!

His ambition was to create what he called, ‘A Sailor’s Power boat’.

While designing the hull, Mark and his team of naval architects ‘stood on the shoulders of giants’ and studied the most sophisticated concepts in the science of fluid dynamics.

Their work was informed by the research databases of both NASA and the US Navy. This high-level study led them to incorporate four key features into the sculpting of the hull’s form.

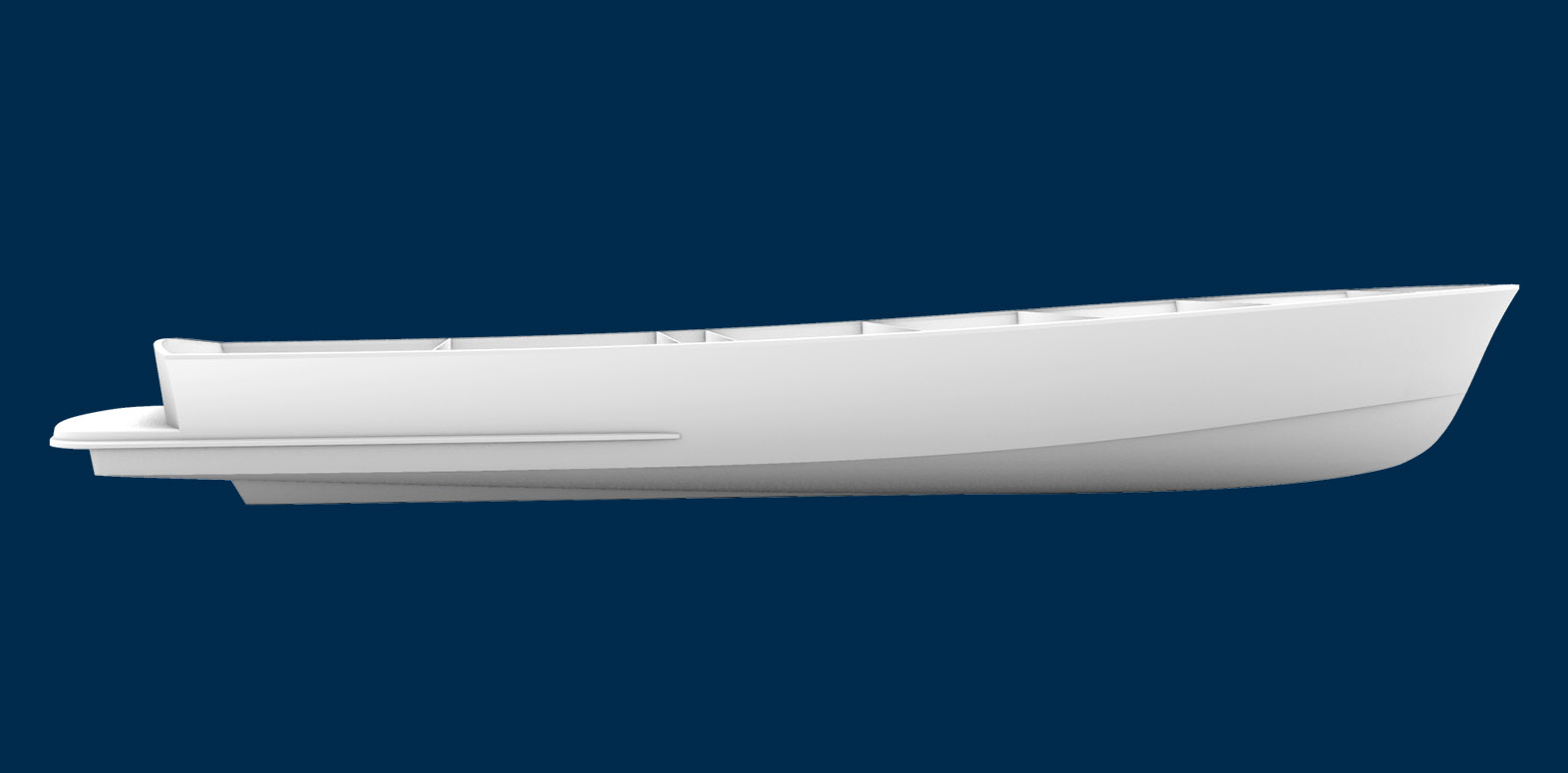

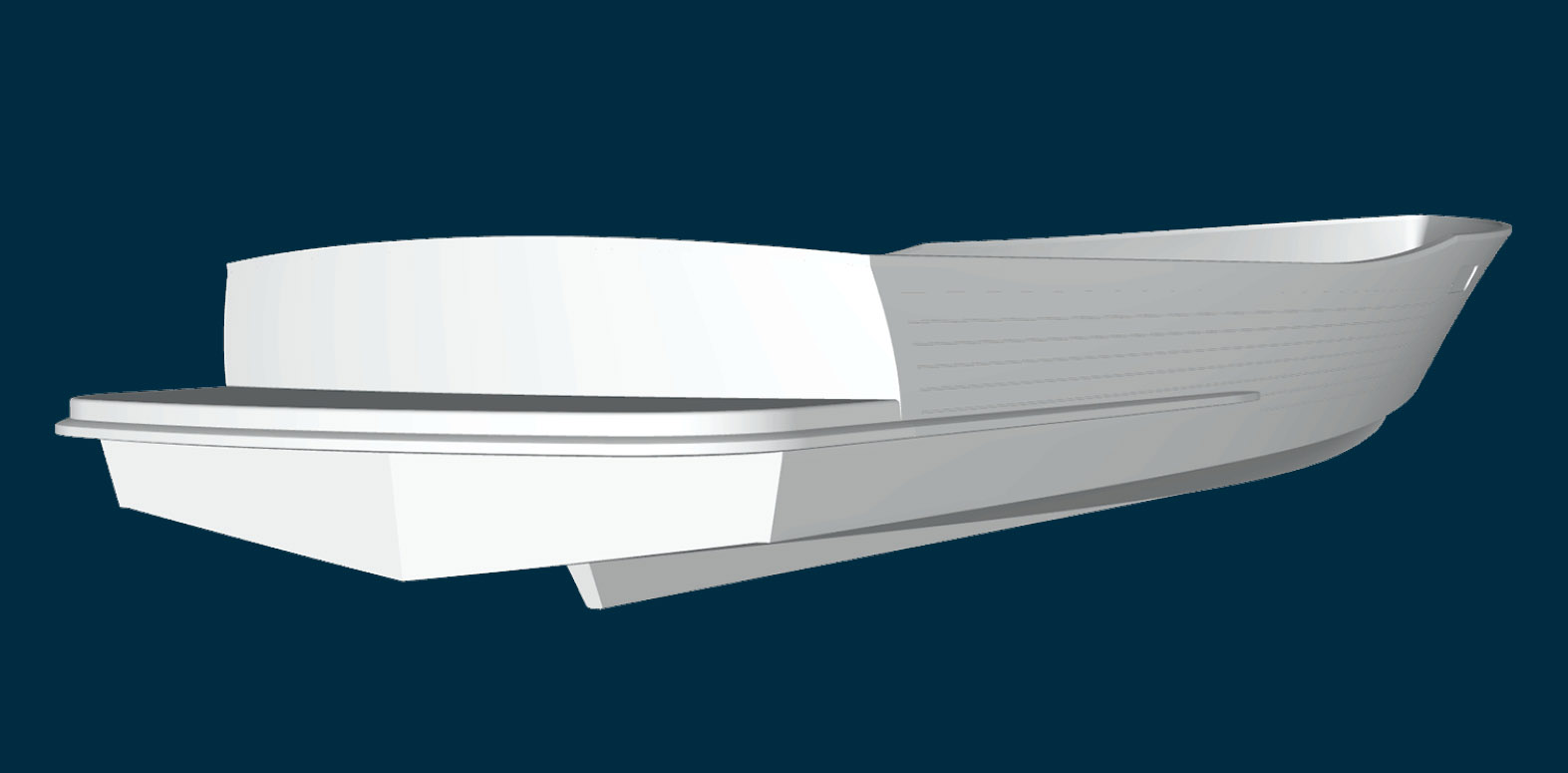

The first, and perhaps the most obvious attribute, is the fine entry of the hull into the water. The blade-like bow splits the seas, creating minimal resistance and helps maintain a level attitude.

In so doing, the hull works to maximum efficiency and delivers an unusually soft ride in all conditions.

The second design feature is the flare you’ll see amidships. This graceful curvature, clearly reminiscent of ocean racing yachts, rolls the seas away from the hull and adds buoyancy.

Beneath this section of the boat, the stem has softened and is subtly rounded to reduce the impact of the waves. This increases stability and gives greater control in rough water.

The third feature, while no means unique to V-Warp® hulls, is the taper that runs the length of the waterline.

However, this works in concert with the flare to provide stability underway. It also reduces drag by creating lift which optimises speed and efficiency in helping the boat reach plane speed more easily.

The fourth feature is not immediately apparent. Seen from beneath the waterline, the area beneath the transom is unusually flat. This increases lift while keeping the bow engaged, reduces drag and is optimal for both shafts and pods as it reduces turbulence in front of the props.

With a deadrise of only 6-8 degrees, the hull remains stable at speed with little or no pounding and remains stable at rest with no rocking or slapping.

A hidden virtue of these features is how little of the hull is beneath the surface of the water. But this shallow draught is, in large part, attributed to the weight reduction of our construction process and the exotic materials we use.

In choosing the materials with which we build the V-Warp hull, we have two over-riding concerns:

Minimise the weight, maximise the strength.

To achieve this, the hull is formed from a sandwich of premium grade e-glass with a closed-cell, foam core. This light and highly buoyant combination of materials is then vacuum infused with the highest-grade of epoxy resin available, a modified epoxy called Vinylester.

The result, while reducing weight, is exceptionally strong and has the added benefit of being virtually impervious to blistering caused by osmosis.

The process we follow is painstaking.

It requires a dedicated and choreographed team to ensure the perfect ratio of resin to material throughout the entire length of the hull. In so doing, we can control the necessary variability of thickness from stem to stern.

In further pursuit of weight reduction and strength, and using a similar infusion process, the deck and superstructure are formed from unidirectional and multi-axial carbon fibre.

With a hull form that is exceptionally efficient in the water, with materials that reduce weight while enhancing strength, it is our build philosophy that delivers the last pieces of the puzzle.

Rigidity and Balance.

While these construction techniques and processes are fundamental to the success of V-Warp technology, ultimately this is a story about synergy – the power of three design features to deliver exponentially superior results.

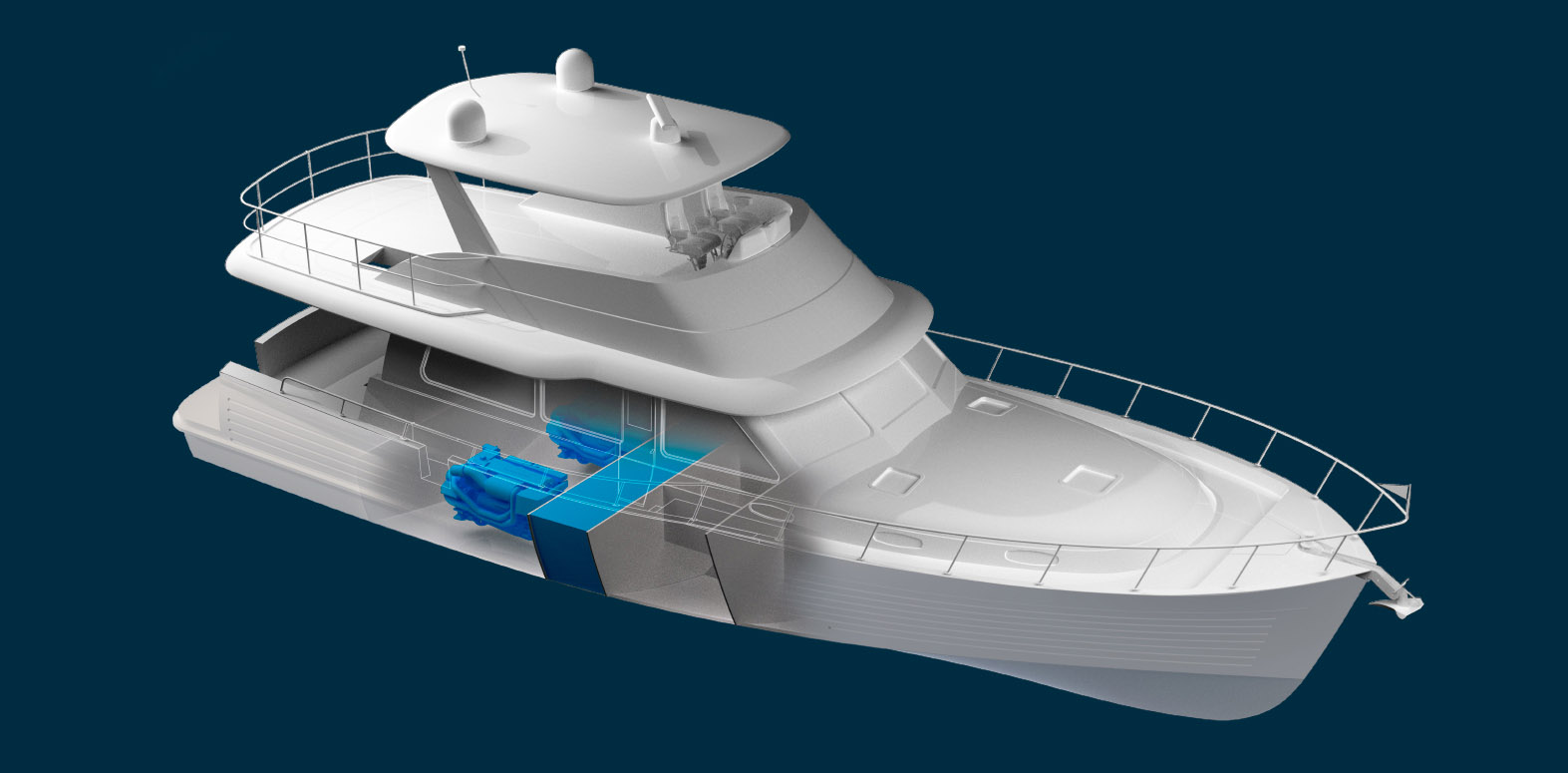

Unlike many other manufacturers who use a rather flimsy system of tabs and liners, a V-Warp® hull is fused directly to all the bulkheads, to the carbon fibre deck and superstructure and to all the fixed furniture that is installed on board – beds, seating and cabinetry.

This reciprocal engineering creates a structural matrix we call a ‘torsion box’. Within this taut construction, each component strengthens the others and creates a stiffness, a rigidity that delivers our characteristically soft, quiet ride – no rattles, no squeaks.

Central to this build philosophy is the positioning of the large mass components.

The engines and full beam, baffled fuel tank are positioned to ensure perfect transversal and longitudinal equilibrium. This poise and balance are further enhanced by a lowered centre of gravity and reduction of weight – a direct result of using carbon fibre in the deck and superstructure.

This configuration leads to extraordinarily stability and responsive handling in all conditions.